50% تخفیف تا 35000 تومان، تمدید طرح عضویت فریلنسری و دریافت تیک آبی پروفایل، با کد تخفیف LF-a8cf8bb فقط تا1 اسفند

Mahdi1983

Freمن یک متخصص طراحی با هوش مصنوعی هستم که به انواع مختلف طراحی و تدوین نوین با هوش مصنوعی و همچنین طراحی با نرم افزارهای ایلوستریتور و فوتوشاپ مسلط می باشم. مدت 5 سال هست که فریلنسر هستم.

تحصیلات

- کارشناسی ارشد طراحی و شناسایی انتخاب مواد از دانشگاه دولتی کاشان- ۱۳۹۴ الی ۱۳۹۷

1394 - 1397 دانشگاه دولتی کاشان - فوق لیسانس طراحی،شناسایی و انتخاب مواد

- طراحی و شناسایی انتخاب مواد (متالورژی) از دانشگاه علامه- ۱۳۸۱ الی ۱۳۸۵

1381 - 1385 دانشگاه علامه - لیسانس طراحی و شناسایی انتخاب مواد (متالورژی)

سوابق شغلی

- بنده به عنوان کارشناس ارشد طراحی و تکنولوگ جوش در شرکت مهندسی فولاد مبارکه مشغول بکار می باشم. شرکت مهندسی فولاد مبارکه مهر جی فعالیتهایی در تمام مراحل زنجیره فولاد از طراحی تا اجرا انجام میدهد، ضمن آنکه سیستمهای مدیریتی و آموزشی را فراهم میسازد و با ارائه خدمات فنی کارگاهی و پیمانکاری به پروژهها پشتیبانی میکند. مأموریتش بومیسازی فناوری و ارائه پشتیبانی کامل مهندسی برای صنعت فولاد ایران است.

1390 - 1404 کارشناس ارشد طراحی و تکنولوگ جوش - شرکت مهندسی فولاد مبارکه

- بنده به عنوان متخصص هوش مصنوعی در گالری آموزش مشغول بکار می باشم.شرکت گالری آموزش بزرگترین پیج آموزشی هوش مصنوعی در ایران می باشد که با حدود ۱ میلیون فالوور، انتشار دورهها، ویدیوهای کوتاه و نکات کاربردی هوش مصنوعی موبایلی و همچنین ارائه دورههای استراتژیک مانند «دانشگاه پولسازی»، «مانی میکر» و «مانی مستر» برای کسب درآمد دلاری از طریق هوش مصنوعی با موبایل شاخص است.

1399 - 1404 طراح و متخصص هوش مصنوعی - شرکت گالری آموزش

دستاورد ها

- Tungsten inert gas (TIG), as an arc welding that uses a non-consumable tungsten electrode to produce the

weld, is widely used to weld aluminum alloys. However, development of some defects such as porosity and

undercutting which form during TIG welding may decrease the quality of the weld. Processing of the weld

by Friction stir processing (FSP) is a method to enhance the weld quality. In the current work, in a new try,

the weld area produced by TIG is processed by FSVP (friction stir vibration processing). In this process, the

workpiece is vibrated normal to processing line while FSP is carrying out. The results show that FSVP is

more beneficial than FSP. The grain size of FSV processed specimens is lower than FS processed specimens

and the strength and ductility of the former specimens are higher than the latter ones. These can be related

to the effect of workpiece vibration during FSVP which enhances the straining of material in processing

zone. It results in more dynamic recrystallization and correspondingly lower size grains are developed.

FSVP is a good alternative for FSP and it is recommended for application in industry.

1397 - Tungsten inert gas (TIG), as an arc welding that uses a non-consumable tungsten electrode to produce the

weld, is widely used to weld aluminum alloys. However, development of some defects such as porosity and

undercutting which form during TIG welding may decrease the quality of the weld. Processing of the weld

by Friction stir processing (FSP) is a method to enhance the weld quality. In the current work, in a new try,

the weld area produced by TIG is processed by FSVP (friction stir vibration processing). In this process, the

workpiece is vibrated normal to processing line while FSP is carrying out. The results show that FSVP is

more beneficial than FSP. The grain size of FSV processed specimens is lower than FS processed specimens

and the strength and ductility of the former specimens are higher than the latter ones. These can be related

to the effect of workpiece vibration during FSVP which enhances the straining of material in processing

zone. It results in more dynamic recrystallization and correspondingly lower size grains are developed.

FSVP is a good alternative for FSP and it is recommended for application in industry. iMAT

Mahdi1983

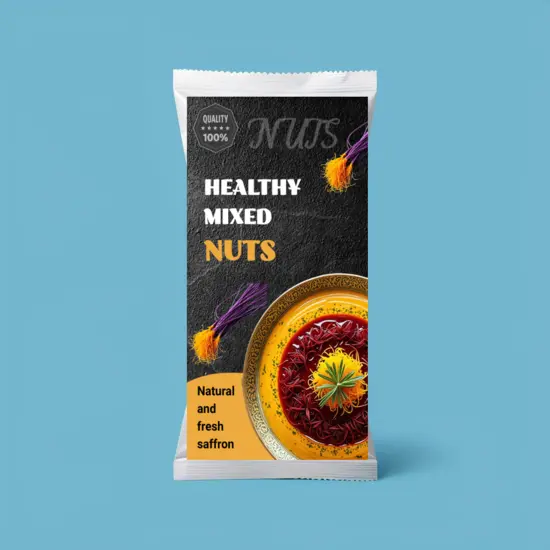

طراحی موکاپ شرکت خارجی بسته بندی زعفران

هیچ سرویسی ثبت نشده است